Real-Time Testing System for Wind Power Generation Machine

Power & Energy , Taipei, Taiwan

Project Introduction: Project Introduction:

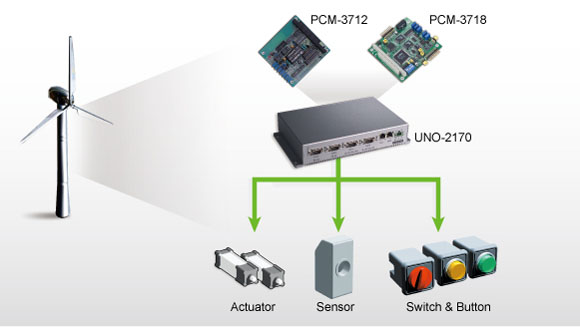

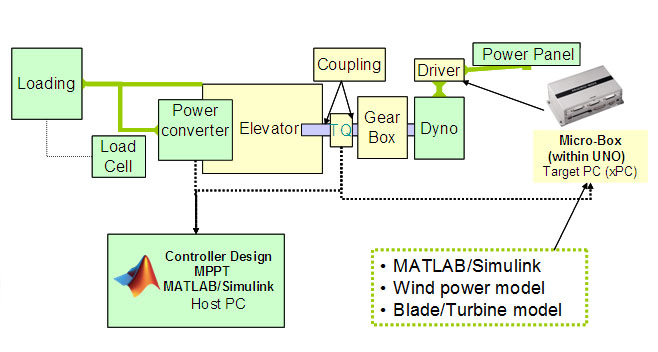

The INER (Institute of Nuclear Energy Research) in Taiwan uses a Micro-Box Real-Time System to create a "Wind Power Generation Simulation Platform", which simulates the wind and blade models theybuild in Simulink®. Through this unique solution, INER can modulate the speed of the dynos based on actual wind direction and strength. Micro-Box is an affordable and robust multi-function platform for rapidly controlling prototype and hardware-in-the-loop test applications. The Micro-Box System is installed with Advantech’s UNO-2170, PCM-3712, and PCM-3718.

System Requirements:

INER wanted to develop a simulation & test station for their wind power generation machines. To do so, they needed a rugged and robust real-time system to run hardware-in-the-loop testing. Therefore, INER made a request for a new system include following requirements:

- Real-time analysis and control systems testing needs.

- Rugged, high-performance industrial PC which is fanless, low-power consumption design, sturdiness, compact size and also can support all standard PC peripherals.

- Standalone ability, xPC self-installed software tools are able to run on stand-alone mode. And users can burn the pre-set model to CF card without connecting through internet.

Project Implementation:

Software

MathWorks MATLAB/Simulink, Real-Time Workshop (C-code generation), and xPC Target toolbox

Hardware

Terasoft Micro-Box includes:

System Diagram:

Function Block:

System Description:

The customer used Simulink to build their physical wind and blade models, and a Micro-Box (embedded with Advantech’s UNO & PCM devices) to create a “Wind PowerGeneration Simulation Platform” for the HIL simulation. The goal of the simulation is to gauge the efficiency and performance of their power generation machines, including stress-testing. From the results of HIL simulations, they can then modulate the speed of dynos according to the actual wind direction and strength, driving the shaft of wind power generator.

Conclusions:

INER’s engineers need to run real-time analysis and control system testing to test the wind power generation machines, and the Micro-Box offers an excellent combination of performance, compact size, sturdiness, and I/O expandability. By integrating Advantech’s UNO-2170 to customize various requirements and integrating MATLAB/Simulink and related control modules, the engineers can conduct real-time modeling and simulationof control systems, rapid prototyping, and hardware-in-the-loop testing without the need of manual code generation and complicated debug processes. This results in significant cost savings and reduced development time.

|